CONVENTIONAL GRINDING WHEELS

Spring grinding wheels

Need a uniform precision grinding solution for spring ends?

We specialise in constructing grinding wheels with countersunk nuts for spring manufacturers. Designed to be used with all leading grinding machines, they are made with next-generation abrasives for high removal rates and low wear.

Resinoid or CBN and diamond grinding wheels for spring grinding

Ermoli grinding wheels are designed for precision grinding and finishing spring ends. Ideal for ensuring a uniform flat surface, they are used for grinding compression, torsion, and extension springs. These grinding wheels ensure the high-quality finish that is vital for the stability and efficiency of the springs.

Delivery time for grinding wheels is 45 days.

Available dimensions for spring grinding wheels

The optimisation of compounds and bonds allows us to create grinding wheels that grind ends with uniform precision, ensuring that the surfaces of the spring are perfectly flat, thereby improving their stability and performance.

Designed to withstand heavy-duty work cycles, Ermoli spring grinding wheels offer lasting durability while maintaining their abrasive capacity over time, reducing the need for frequent replacements.

Designing with absolute precision enables us to create grinding wheels that are suitable for machining different types of springs (compression, torsion, and extension) and a range of elastic materials, including tempered steels and special alloys.

Thanks to their ability to keep temperatures low while machining, Ermoli spring grinding wheels reduce the risk of any distortions or loss of the material’s elastic properties, ensuring a longer lasting end product.

Special requirements?

Our consultants are always available to provide a comprehensive consultation during which they analyse your goals, machinery, vacuum systems, and equipment.

This enables us to help you to choose the best grinding wheel for your specific needs.

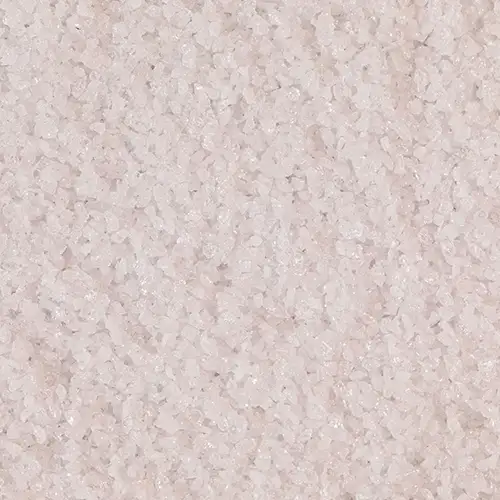

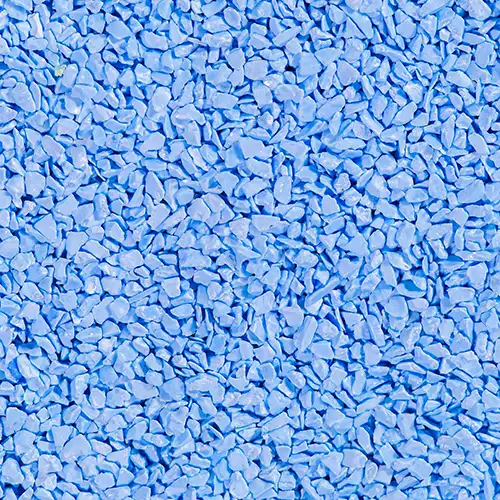

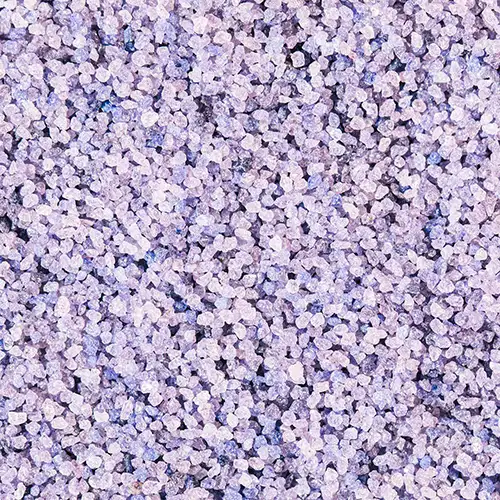

Our material library

Our corundum, silicon carbide, CBN and diamond grinding wheels are created with unique formulas specially developed by our engineers to meet all your stock removal requirements.

Sectors utilising spring grinding wheels