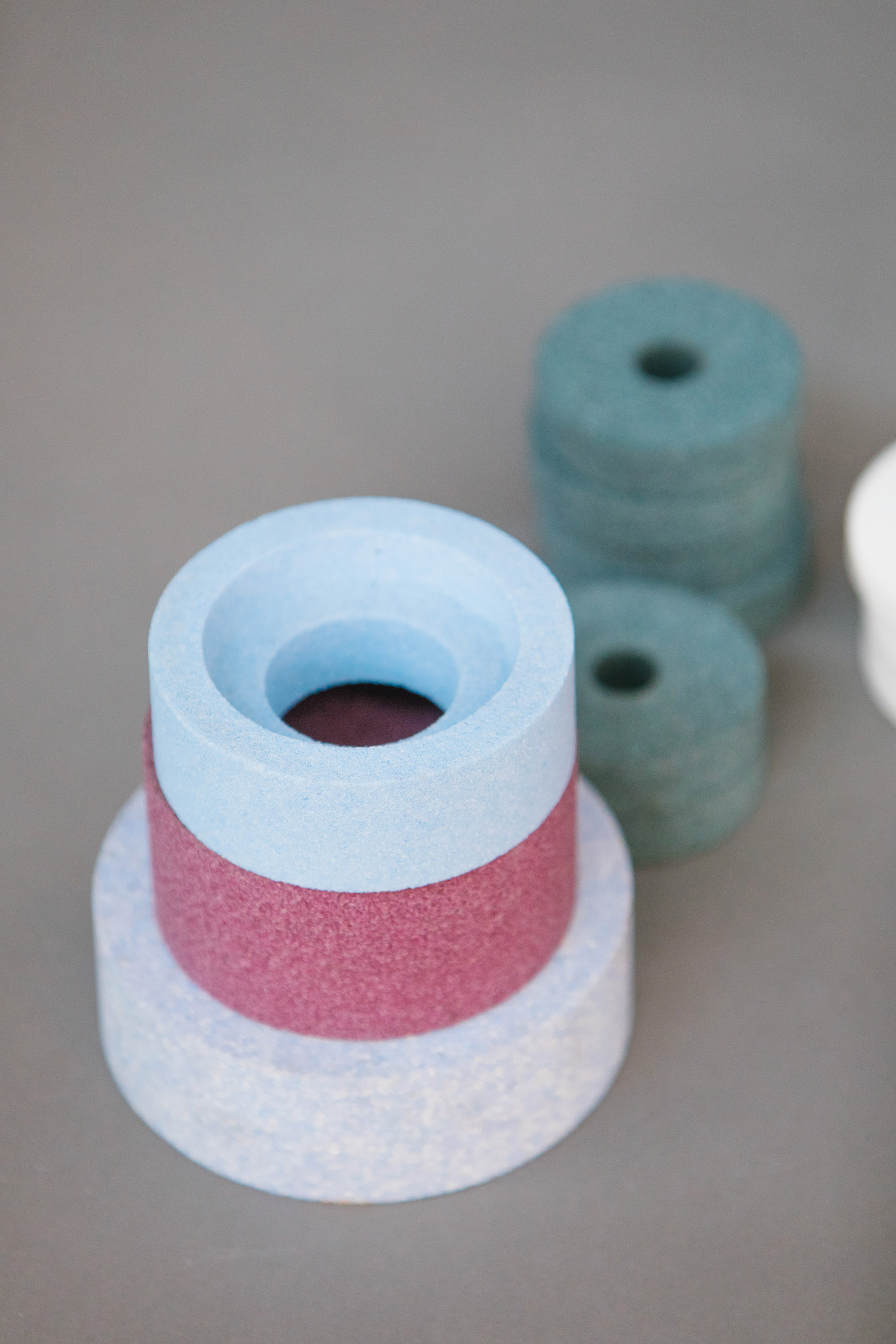

La Mole Abrasivi Ermoli è una delle aziende leader italiane nella produzione di mole abrasive.

La nostra azienda, proprio come un albero secolare, ha radici profonde.

Affondare le radici nella storia, è per noi un valore aggiunto: significa saper conciliare conoscenze del passato con tecnologie e materiali del presente, nel nome di un’innovazione costante, per raggiungere la massima efficienza e qualità di prodotti e servizi.